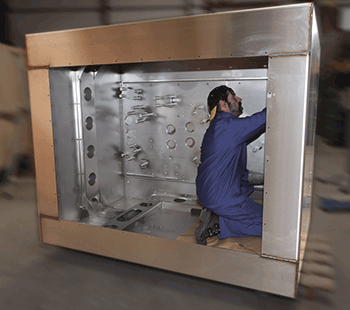

Spenge. Breaking new ground and finding innovative solutions for complex structural engineering solutions - these are challenges that MODERSOHN, as a manufacturer of system products for the construction industry, is constantly facing. In this respect, it is not surprising that the manufacturer and distributor of Stainless steel façade fastening systems is now also moving into areas of virtual simulation such as structural analysis. "Our job is to manufacture high-quality Support brackets as well as to sell tested quality," explains Jürgen Matzelle, one of the two managing directors at MODERSOHN, and continues: "We see it as our responsibility to offer our customers the best possible advice and recommendations for our products. To this end, we work closely with testing institutes and accredited companies. With the new software, we provide optical and mathematical proof of the lowest possible heat permeability with our fasteners".

Since the middle of the year, the graduate engineer has been testing with great success a software system for finite elements analysis with which structural-mechanical problems can be adapted, automated and subsequently also parameterised.

This enables the company to run through a wide variety of scenarios in structural design and to offer optimum product solutions for project planning.

Why perform a thermal analysis?

MODERSOHN already meets the growing demand of specialist planners and engineers to avoid heat loss during façade planning and to keep the U-value as low as possible by using increasingly slim support structure brackets made of Stainless steel or Lean Duplex steel. By means of finite element analysis, the planning companies are also offered the mathematical proof for optimal heat management.

What are the advantages of finite element analysis?

The findings of the analysis serve both as a measure to save energy and reduce operating costs, and the aspect of planning security for the engineer and the client is also further supported.