Visually and technically sophisticated stainless steel surfaces have been offered to business customers since mid-May as a new service of the NiroFix® department.

In order to reduce the risk of crevice corrosion on Stainless steel and Lean Duplex steel as well as unsightly fingerprints on very smooth surfaces, MODERSOHN has developed a special surface finishing process consisting of electrochemical removal and mechanical blasting. The result is a very insensitive surface on which the machining marks are removed that would be highly visible in conventional electropolishing without the additional blasting.

"MODERSOHN's uniform and less complex abrasive blasting method in combination with electropolishing and pickling not only allows (industrial) components made of high-strength Stainless steel to be classified one corrosion class higher, it also gives them a decorative surface that has no visual imperfections," explains Sascha Berg, welding specialist and department manager for the custom-made products and industrial components division of the company based in Spenge, Herford district.

This method can be applied to small parts as well as to larger individual workpieces made of electropolishable material. "Our method is particularly suitable for small and sensitive parts because electropolishing is a distortion-free process and no mechanical, thermal or chemical stresses emanate from it," continues Mr Berg, who is also a master metalworker, in his explanation.

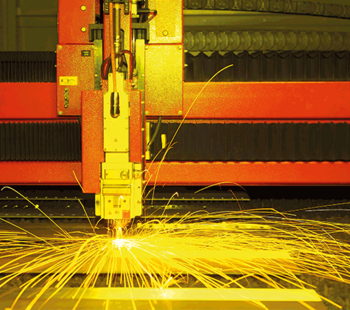

When processing Lean Duplex steel and Stainless steel, Wilhelm Modersohn GmbH & Co. KG takes the utmost care and precision. Both before and after surface processing, material and quality tests are carried out in the company's own testing laboratory using special testing equipment. All Stainless steel sheets to be processed are stress-relieved in advance and the cut parts are straightened afterwards.

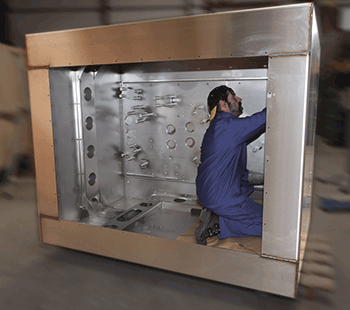

At Wilhelm Modersohn GmbH & Co. KG there are two basin sizes available for electropolishing: the smaller basin measures 800 x 450 x 500 mm, the larger 3,000 x 700 x 750 mm (length x width x filling height).

Mr Berg sees areas of application, for example, in medical technology, the food industry, environmental technology and sewage treatment plants, water treatment and surface finishing.

About the company

Wilhelm Modersohn GmbH & Co. KG is known in the field of Stainless steel processing and the production of Fastening elements above all for manufacturing series and custom-made products from high-alloy and special stainless steels. For years, the company has relied on duplex steels, especially the so-called "Lean Duplex" steels (1.4062, 1.4162, 1.4362), whose market introduction in the German construction industry has been personally championed by Managing Director W. Modersohn since 2002.

Contact person:

Wilhelm Modersohn GmbH & Co. KG

Vivian Dieckmann

Head of Marketing

Industriestraße 23

32139 Spenge

T: +49 5225 8799-472 | F: +49 5225 8799-45

E-Mail: dieckmann@modersohn.de | Internet: www.modersohn.eu

![[Translate to Englisch:] Handrail of a stainless steel railing machined with the new surface finishing process from MODERSOHN®.](/fileadmin/user_upload/Elektropoliertes_und_gestrahltes_Gelaender.png)