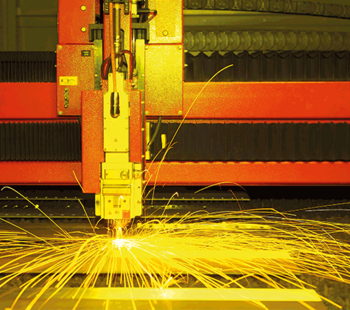

Production process at MODERSOHN for precise and distortion-reduced cutting of metal sheets and metal plates made of e.g. stainless steel, copper, brass, bronze, aluminium; with the aid of a high-pressure water jet and mixed abrasive agent (garnet grain). With up to 6,000 bar, especially thick metal sheets (from 12 mm) can be cut economically, so that there is hardly any or no burr on a very right-angled cutting edge. Cutting precision and cutting costs depend on the cutting speed and range from a simple separation cut to an already very flat quality cut.

- Construction

- Industry

- References

- Our Services

- Worth knowing

- Downloads

- Company

As an independent representative of fastening systems from the company Lutz from Wertheim, Wilhelm Modersohn sen. had recognised early on that there was a great demand in the market for fastenings in the area of masonry facades. In March 1970, he and two employees founded the company, which today has over 140 employees.