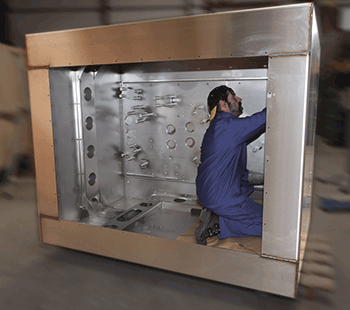

At MODERSOHN, tungsten inert gas welding (TIG welding) is a very important joining process for all components supplied to the plant and mechanical engineering industry. Many of the housings as well as gutters, tubs, filigree frames and racks are manufactured using this welding process.

This creates an arc between a tungsten electrode and the workpiece(s). A gas mixture (argon-helium) is used during the welding process to protect against oxidation by ambient oxygen.

If two workpieces are not directly fused together in this way, it is also possible to add a filler metal using so-called TIG stick electrodes.

The advantage of the TIG process is a low heat input, which minimises distortion, especially with filigree and thin-walled components.

However, the TIG process is considerably slower than the MAG process and therefore more cost-intensive.

- Construction

- Industry

- References

- Our Services

- Worth knowing

- Downloads

- Company

As an independent representative of fastening systems from the company Lutz from Wertheim, Wilhelm Modersohn sen. had recognised early on that there was a great demand in the market for fastenings in the area of masonry facades. In March 1970, he and two employees founded the company, which today has over 140 employees.