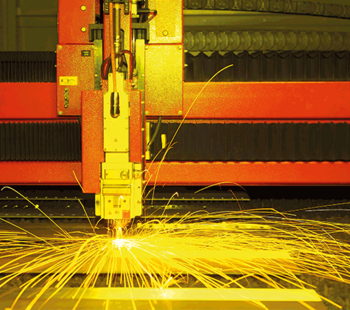

Laser cutting is a manufacturing process at MODERSOHN for precise and inexpensive shape cutting of sheet metal or metal plates, e.g. stainless steel, normal steel (ST) or aluminium. Our 4 and 6 kW systems can cut sheet metal up to 25 mm thick (stainless steel) and 2,000 x 4,000 mm in size.

Laser cutting is operated with high-alloy materials (e.g. stainless steel) as melting with a laser beam focal point on the lower sheet side with nitrogen, and with unalloyed or low-alloy materials (mild steel ST) with a laser beam focal point on the upper sheet side, with oxygen as cutting gas.

- Construction

- Industry

- References

- Our Services

- Worth knowing

- Downloads

- Company

As an independent representative of fastening systems from the company Lutz from Wertheim, Wilhelm Modersohn sen. had recognised early on that there was a great demand in the market for fastenings in the area of masonry facades. In March 1970, he and two employees founded the company, which today has over 140 employees.