- Construction

- Industry

- References

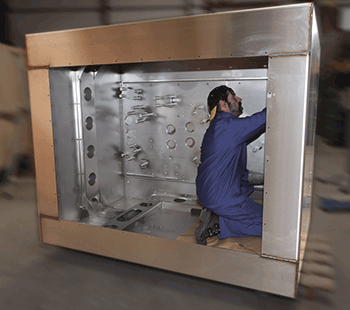

- Our Services

- Worth knowing

- Downloads

- Company

As an independent representative of fastening systems from the company Lutz from Wertheim, Wilhelm Modersohn sen. had recognised early on that there was a great demand in the market for fastenings in the area of masonry facades. In March 1970, he and two employees founded the company, which today has over 140 employees.

Glossary

- MAG-welding

- Metal active gas welding (MAG welding) is the most important welding process at MODERSOHN and is used for most of the fastening parts in the building industry.

- Manufacturer qualification class E

- In the field of joining and welding technology, valid proof of suitability which must be regularly renewed in the company by external inspectors (most of them by employees of a welding training and testing institute [SLV]).

- Masonry connection

- It is important that masonry walls are connected to each other in a non-positive way, e.g. when inner walls of masonry meet load-bearing outer walls, and then even very different types of masonry meet.

- Masonry reinforcement

- Masonry reinforcement is understood to be the stabilisation of the masonry wall (disc) in the hardened mortar composite, by adding profiled force-absorbing material in the masonry joints.

- Masonry support

- The term masonry support refers to the fixing of a wide variety of masonry blocks, with supporting and retaining anchors in the double-shell wall structure of the facade.

- Mn (manganese)

- Increases tensile strength, austenitizing agent, Ni replacement (danger of manganese sulphides, less corrosion resistance in acidic environment).

- Mo (molybdenum)

- Increases corrosion resistance, deteriorates toughness Duplex steel → reduces temperature resistance → Sigma phase (650 - 850°C).

- Mortar anchor

- Mortar anchor is another term for the bonded anchors, which is mainly used for load-bearing and retaining anchors in the natural stone fixing sector.

- MOSOTherm

- MOSOTherm is an insulation system for the reduction of thermal bridges in the area of facade fixing systems.

- Mounting systems

- General generic term for all supports and properties that are designed according to a basic principle to connect building structures with each other. The fastening system does not always have to be a separate component.

- Mounting systems made of stainless steel

- Designation for all stainless steel fastening components which, according to a planned principle, enable the assembly of the structure or plant at the project site (e.g. construction site).